Everything you need to know about conveyer belts

Plastic belt conveyors are the result of technological

improvements in the field of material sciences. The belts are made of material

that is suited for use in food and other industries where inertness of the

conveying medium is most desirable. The conveyor belt allows for automatic

handling of food products and its inertness is attested by the authorities.

Many manufacturers of food products test their assembly lines for undesirable

reactions with their products, only to find that such conveying mechanism

allows in maintaining the highest standards. Conveyor belt cleaners is also

highly important to ensure proper functioning.

The benefits of plastic over other types

Besides the chemical inertness, there are many reasons for

choosing plastic belt conveyors. The light weight operation of the conveyor

modules is one important reason. The modules commonly feature polycarbonate

construction and allow for easy connection to make long assembly lines, with

different degrees of inclines. The systems operate at least dB levels as compared

to other systems and that too despite higher drive motor rpms. Assembling the

system is easy. Many production unit owners prefer to convert their existing

systems into plastic conveyors by mounting sprockets to a shaft by changing

rollers. Worker safety is greatly improved even when overhead systems are used.

Most belts will work with different modular systems. So if you have a system

then a wide range of conveyor belts can be used with it.

Working with a variety of products

Plastic conveyor systems come with a variety of working

surfaces which allow for use with different products. Sprockets or other

variants prevent dead zones, i.e. where a product tends to stop on the conveyor

as the surface is even and suits the product being conveyed. Traditional

rollers frequently present with such problems. The Plastic Belt Conveyors is

highly flexible which in turn allows for improved conveyance of the product and

also minimizes product damage. The flexibility allows for side-flexing and

makes for better utilization of ground space in addition to decreased

production time.

Low cost of maintenance

The cost of maintenance is lower compared to other types of

systems as repairs can be performed without removing the belt. They can be

washed down, something that cannot be done with fabric variants. The provision

for washing and restoring hygiene standards is another reason why the food and

meat processing industries prefer plastic Conveyor systems. Washing can be done

with appropriate cleaners or even soap water. Fabric belts on the other hand

are not easy to clean and after prolonged use, can become a hindrance to

maintaining hygiene standards in Canada. They have to be removed to be cleaned

which disrupts an entire day of work. That apart, these fabric belts have to be

replaced frequently as the wear is higher compared to their plastic

counterparts.

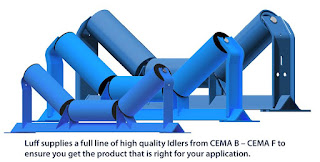

In case you’re willing to know anything more about conveyor

belt or conveyor belt cleaners, then feel free to visit LUFF Conveying

Performance. For more details, visit: https://luffindustries.com/

Comments

Post a Comment