Different Accessories of Conveyor belt Systems

Say it the shopping mall’s entrance, airports, newspaper printing agencies or other such businesses where the items need to be transported over a short distance, you can easily locate the belt conveyor systems there. Though the main function performed by these belts is the transportation of the heavy objects from one point to another, they are also used in other applications, like escalators.

The Overland conveyor belt system is the mechanical apparatus which has two or more pulleys attached to a continuous moving belt. The pulley that moves the belt is known as drive pulley, while the unpowered pulley is known as an idler. However, no matter what business you are into and what purpose you use the conveyor belts for, you should always focus on quality while buying the conveyor belts and their accessories. Though conveyor belt systems have their life which depends on their type, size and extent of use, there comes the times when the parts of these systems get damaged and need to be replaced.

Whatever may be the reason for the failure of conveyor belt parts, you should always call the professionals for fixing the issues. And when it comes to replacing the parts, you should always buy the original conveyor parts in Overland, from a reputed and authorized provider. No doubt the professionals can guide you to choose the right parts, but it is necessary to have basic knowledge about these parts so that you can differentiate between the available options and locate the right one for your system. This knowledge will further help you to evaluate the professionalism of the service providers.

So, here are the main accessories that are used in conveyor belt systems.

1. Conveyor belt scrapers

The polyurethane DEL/CLEAN scraper is used to remove unwanted items from the conveyor belts. These scrapers come with a range of features which include:

- Fast and easy assembly

- Optimum hygiene

- Can be used with a new or an existing system

- Easy to maintain

- Suitable for all kinds of conveyor belts

- No lateral misalignment

2. Guide Rollers

Guide rollers are used to provide strength, durability and corrosion resistance. They are made using different materials but the guide rollers made of urethane material are considered better than the steel guide rollers. Here are the features of quality guide rollers:

- Full-length threading

- Easy installation

- Ultimate belt control

- Reduced chances of severe belt damage

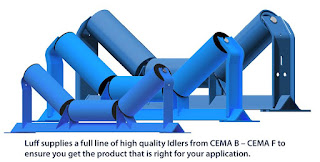

3. Composite Idlers

These are used to reduce the weight of rollers and ensure smooth functioning of the conveyor belt system. Main features of good composite idlers are:

- Corrosion resistant construction

- Achieve more sound emission reduction

- Available in different diameters

- Abrasion resistance

There are many other accessories of the conveyor systems which include belt brush cleaner, moisture seal, rollers, frames, retro protector and more. It is recommended to buy these Overland conveyors and their accessories from a company that designs and manufactures them on its own. Otherwise, you may encounter the size and compatibility issues. To get more information, visit Luff Industries.

The Overland conveyor belt system is the mechanical apparatus which has two or more pulleys attached to a continuous moving belt. The pulley that moves the belt is known as drive pulley, while the unpowered pulley is known as an idler. However, no matter what business you are into and what purpose you use the conveyor belts for, you should always focus on quality while buying the conveyor belts and their accessories. Though conveyor belt systems have their life which depends on their type, size and extent of use, there comes the times when the parts of these systems get damaged and need to be replaced.

Whatever may be the reason for the failure of conveyor belt parts, you should always call the professionals for fixing the issues. And when it comes to replacing the parts, you should always buy the original conveyor parts in Overland, from a reputed and authorized provider. No doubt the professionals can guide you to choose the right parts, but it is necessary to have basic knowledge about these parts so that you can differentiate between the available options and locate the right one for your system. This knowledge will further help you to evaluate the professionalism of the service providers.

So, here are the main accessories that are used in conveyor belt systems.

1. Conveyor belt scrapers

The polyurethane DEL/CLEAN scraper is used to remove unwanted items from the conveyor belts. These scrapers come with a range of features which include:

- Fast and easy assembly

- Optimum hygiene

- Can be used with a new or an existing system

- Easy to maintain

- Suitable for all kinds of conveyor belts

- No lateral misalignment

2. Guide Rollers

Guide rollers are used to provide strength, durability and corrosion resistance. They are made using different materials but the guide rollers made of urethane material are considered better than the steel guide rollers. Here are the features of quality guide rollers:

- Full-length threading

- Easy installation

- Ultimate belt control

- Reduced chances of severe belt damage

3. Composite Idlers

These are used to reduce the weight of rollers and ensure smooth functioning of the conveyor belt system. Main features of good composite idlers are:

- Corrosion resistant construction

- Achieve more sound emission reduction

- Available in different diameters

- Abrasion resistance

There are many other accessories of the conveyor systems which include belt brush cleaner, moisture seal, rollers, frames, retro protector and more. It is recommended to buy these Overland conveyors and their accessories from a company that designs and manufactures them on its own. Otherwise, you may encounter the size and compatibility issues. To get more information, visit Luff Industries.

Comments

Post a Comment